Selective absorption in the visible spectrum is the first half of the way colorants develop their specific colors. For example, consider a colorant that selectively absorbs all the wavelengths of white light except the red portion in the 600 to 700 nm range. This colorant then transmits and/or scatters the remaining red light, which classifying it as a red colorant.

A colorant that absorbs the red, orange, yellow, blue, indigo and violet portions of white light would appear as a green colorant. The light illuminating an object must contain the wavelengths the colorant will transmit or scatter to develop its inherent color. As an example, if the light illuminating a red apple does not contain any red light the apple will appear black to the observer.

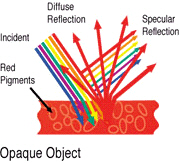

Internal Scattering

Internal scattering is the second half of the effect of pigments when incorporated into plastic materials. After selectively absorbing light, the pigments scatter the remaining colored light, sending it out of the sample and giving the sample its perceived color. Scattering can also contribute to opacity. In the image below, the red pigment particles absorb the blue, violet, green, yellow and orange wavelengths and reflect and scatter the red wavelengths back out of the object, imparting the red color. Note that the specular component of the surface reflection still contains all the wavelengths of the incident light.

Absorption/Opacity

The opacity of a plastic sample is the direct result of absorption and scattering. Pigments and polymers have varying abilities to selectively absorb and scatter light. If a particular pigment and/or polymerís ability to selectively absorb and scatter light is great enough, that pigment or polymer will produce opacity in a plastic sample. This scattering along with the selective absorption of the pigment determines the color and the opacity of a plastic object.

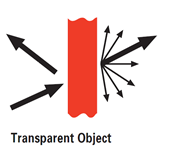

Transparency

The transparency of a plastic sample is directly related to the absence of (or very low amounts of) scattering in a sample. In this case, the colorant and/or the polymer will selectively absorb, resulting in the perceived color. However, instead of scattering the remaining light, the sample lets this remaining light pass through, resulting in transparency.

Two types of colorants are used in plastics: pigments, which are small particles dispersed in the polymer matrix, and dyes, which are actually soluble in the polymer matrix itself. Soluble dyes only absorb light, they do not scatter light, resulting in transparent samples. The ability to let incident light pass through a sample and not scatter that incident light is transparency. An example of this would be the use of a red dye to color automobile taillight lenses made of Lexan* polycarbonate (PC) resin. In this example, the red dye selectively absorbs all but the red light, which it passes through the taillight lens.

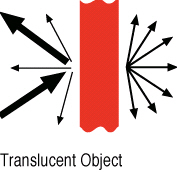

Translucency

The translucency of a plastic sample results from a combination of absorption, scattering and transparency. The contribution of each of these attributes in combination will determine the perceived color and the amount of that color that passes through the sample. Many plastic products fall into this translucency group. Obviously, the perceived translucency of a resin in an application is strongly dependent upon the part thickness and the strength of the light sources illuminating the application. It is important to note that the translucency or opacity perceived by the eye may or may not be captured or interpreted when measured by a color measuring instrument.