There are three major classes of measuring instruments available to the coloring of plastics industry. They are:

- Colorimeters.

- 0/45° and 45/0° Geometry spectrophotometers.

- Integrating sphere geometry spectrophotometers.

Colorimeters

Colorimeters were the pioneers of color measuring instruments. Colorimeters view a sample through at least three filters, measuring the quantity of light reflected from the sample as it passes through each of the filters. The filters were originally designed to mimic the response of the red, blue and green cones of the eye as closely as possible. This, at first glance, seems to have merit, since it attempted to imitate the eye of the standard observer. However, an important deficiency of colorimeters is they cannot separate the pure color from the appearance of an object. Additionally, a colorimeter is unable to detect if an object’s color will appear differently under different light sources. Therefore, colorimeters have limited capability when compared with current technology.

0/45° and 45/0° Geometry spectrophotometers

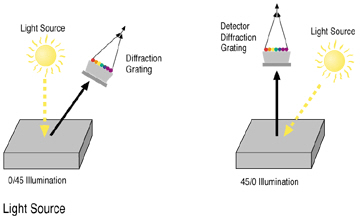

0/45° geometry spectrophotometers illuminate the sample at an angle of 90° while the detector views the sample at a 45° angle. 45/0° geometry illuminates the sample with a beam striking the sample at an angle of 45° while the detector views the sample at an angle of 90°. Many color technologists report that 0/45° or 45/0° geometry spectrophotometric and colorimetric data closely simulates the visual experience. This is advantageous when seeking to match or evaluate color samples thanks to the reported agreement with visual assessments. A distinct disadvantage to this geometry, however, is the inability to examine transparent and translucent samples.

Advantages

+ Mimics visual observations.

+ Minimizes gloss differences.

Disadvantages

- Unable to measure transparent samples.

- Cannot differentiate between color and appearance.